DMT - MADE IN USA

For tools. The continuous surface area is ideal for touching up and cleaning the resin from router cutters and sharpening narrow and fine cutting tool edges e.g. chisels with 1.5-8 mm blade width which might otherwise snag in an abrasive valley . Plastic case, slip-proof rubber base.

The American manufacturer Diamond Machining Technology (DMT) is the founder of interrupted surface technology for diamond sharpening stones, and has been the market leader for diamond-coated sharpening equipment for years. The high-quality sharpening tools are manufactured at the company's headquarters in Massachusetts (USA).

- Monocrystalline* diamond particles guarantee a long service life and excellent material removal

- Uniform grit sizes and a dense diamond distribution for even grinding patterns

- Round recesses prevent clogging due to grinding debris

- Permanently flat and warp-free thanks to supporting plates made of steel or warp-free plastic with a nickel matrix

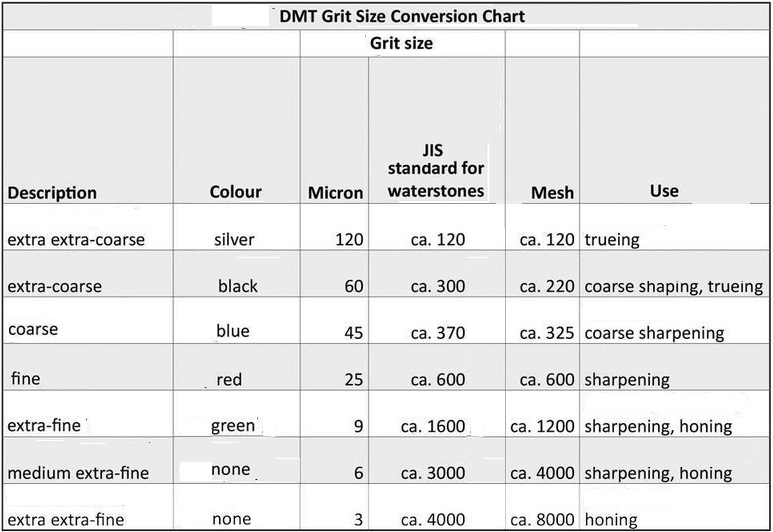

- Colour coding of various grit sizes

- 100 % made in the USA

Monocrystalline* diamond-coated sharpening devices:

Diamond-coated sharpening devices remain permanently flat, and are especially suitable for tools with straight blades, as well as for producing flat surfaces (e.g. backs of plane and chisel blades, plane soles, scrapers). Also suitable for carbide coated cutters, tool steels, HSS and non-metal materials (glass, ceramic, etc.). We recommend moistening diamond-coated sharpening devices with water and grinding with little pressure.

* Monocrystalline diamonds are significantly more wear resistant than the polycrystalline diamonds used to make lower quality diamond sharpening tools.

See

HERE for a correlation table of abrasives used in wood working.