THREADED INSERTS

See HERE for an extensive data sheet.

Threaded inserts belong in a broad category of hardware fasteners known as knock down, have a very wide application and are typically used when wood assemblies are required to be able to be "knocked down" or dis-assembled. Threaded inserts allow the repeated use of any compatible machine screw or bolt with no wear or damage to the components.

We offer inserts in ascending order of strength in ZINC ALLOY, SOLID BRASS and PLATED STEEL. They are available in two basic styles, FLANGED or UN-FLANGED. Flanged inserts may require a slight countersink on the insertion hole to finish flush with the surrounding surface. Un-flanged inserts may be inserted level or below the surface and given, the appropriate insertion mandrel, in multiples to achieve greater holding capacity.

INTERNAL THREAD

Thread options internally are applicable world wide and either METRIC measured in millimetres with a 60 degree thread angle or imperial inch sizes in UNC/WHITWORTH with a 55 degree thread angle. They are incompatible with each other.

(UNC = Unified Coarse is a standard used in America and confusingly uses gauge numbers for sizes under 1/4 inch. What we in Australia may know as a 3/16th inch may be referred to as a 10--24 in US publications - a 10 gauge screw with 24 teeth to the inch. UNC and BSW - British Standard Whitworth, are approximately compatible in sizes up but excluding 1/2 inch ).

EXTERNAL 'THREAD'

The external 'thread' on zinc alloy fittings is cruder than the sharp finned thread on brass and steel variants. To my knowledge there are no commercially available taps to thread the insert hole. We offer fabricated tap assemblies using a threaded insert as the tap. See HERE .

THREAD PITCH

Thread pitch is a measure of the distance between adjacent teeth. Metric pitches are simply measured in millimetres, UNC/Whitworth pitch is a count of the number of threads to an inch of the screw.

Standard Metric Coarse (there is a Metric Fine - rarely encountered) are as follows:

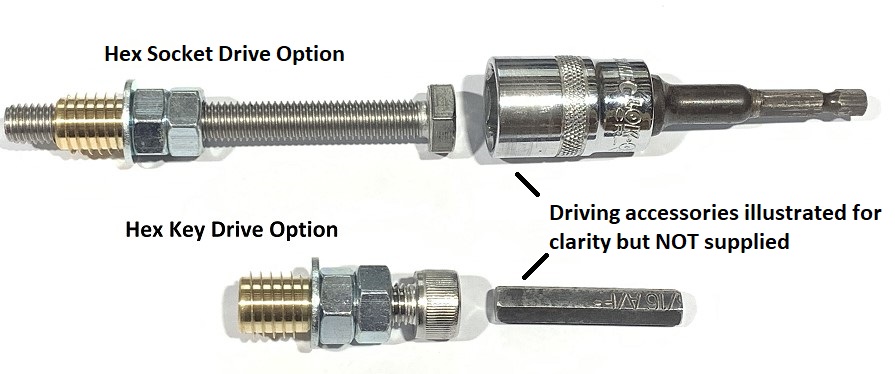

INSERTION

All inserts are best seated using a mandrell as offered below. The zinc versions can be seated using a up-scale allen key - refer to the sizes table below This may be problematic in harder woods. The brass inserts may have a slot for an insertion tool which we don't offer. We do not suggest the use of a screwdriver which may chew up brass inserts.

The root diameter is the diameter of the insert at the bottom of the external teeth and is the minimum diameter of the drilled hole required.

The insertion hole is often varied slightly to accommodate harder woods

Inserts can be inserted at an angle. A pre-drilled, angled, landing flat assists with this, drilled with either a forstner or spade bit.

Given a long enough insertion mandrell it is possible to gang 2 inserts together for greater strength. It may be wise to have a machine tap to finish the job. You can seat the inserts with a little adhesive taking care not to get glue on the internal threads.

Note: We can only source long set screws with a hex head drive so for double or triple gang insertions be sure to order a hex head drive mandrell and not a hex key drive which we can only source in shorter lengths.

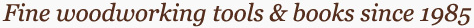

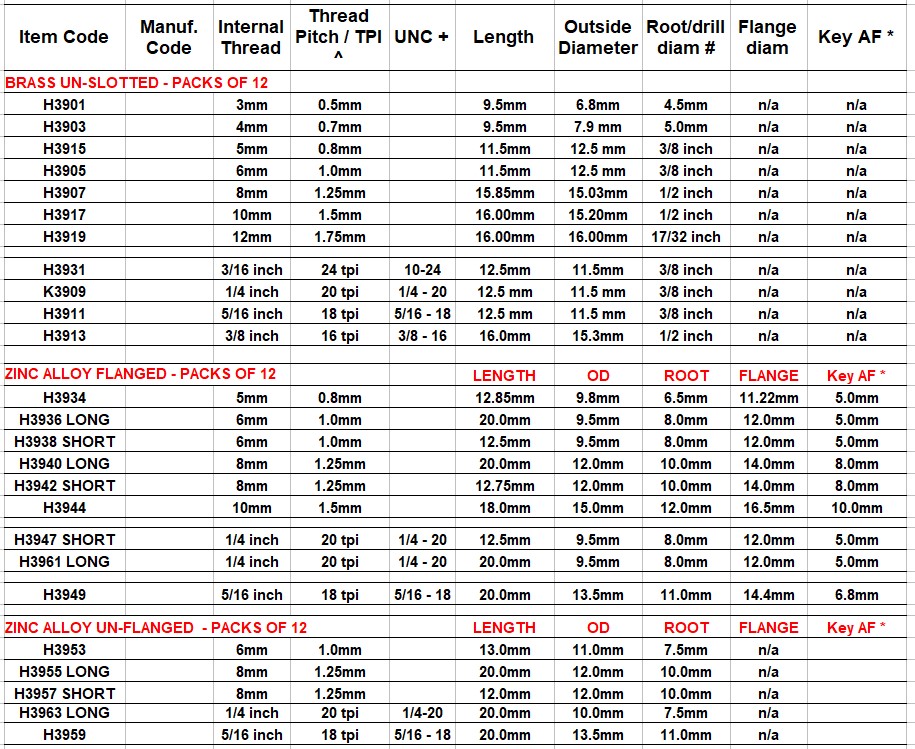

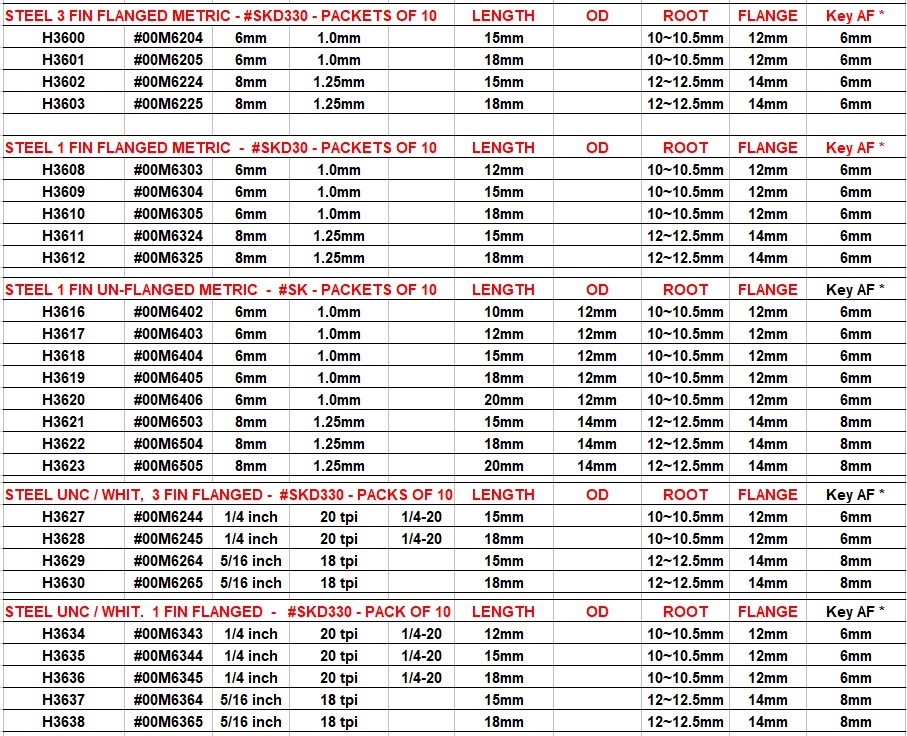

Some Insert Dimensions and drill selection:

Note; Due to supply issues we occasionally source inserts with varying external dimensions. If you are not equipped to manage these variations please confirm the dimensions of current stock before purchase.

Mandrell insertion Options

See HERE

Click HERE to see a comprehensive data sheet on threaded inserts and accessories..

See HERE for a data sheet with links to over 75 of our specialised fasteners