Japanese chef's knives - generically known as hocho - have an unrivalled reputation for edge quality and retention and jaw droppingly beautiful aesthetics.

There are several manufacturing - or perhaps a better word is making - techniques because the best of these hocho are hand made by master smiths. The most renowned technique is lamination where a core of multi layered, high carbon, edge holding steel - often referred to as blue paper or white paper - is forged between rust resistant steel cheeks which serve to cushion the hard core steel, rust proof the majority of the surface of the blade and provide a softer layer where the master smith can leave his 'chop' or insignia.

In the kitchen some formulations of so called stainless 'steel' - critics don't accept it as steel at all - have application as an edge steel for some Japanese hocho and it remains a passionate debate as to whether the stainless formulations match their traditional carbon steel counterparts.

Bear in mind that quality edge tools in woodworking, gardening and the kitchen which use high carbon or tool steel for their cutting edges are subject to rust. A susceptibility to rusting is an unavoidable trade off for the edge taking and holding nature of high carbon steels.

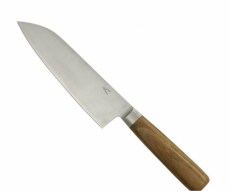

The ancient factory of Tadafusa has been manufacturing high-quality kitchen knives already in the third generation. These hand-forged, 3-layer blades have a core layer made of rust-resistant SLD steel (see below), and due to its high carbon content it lends the knife an excellent sharpness and impressive edge life. The outer layers are rustproof and thus easy to maintain. The handle is made of heat-treated thermic wood (see below) chestnut and is comfortable to hold and work with.

The stainless steel ferrule creates a smooth transition towards the blade. Hardness 60 HRC, rust-resistant, double-bevelled.

SLD Steel: composition - Carbon 1.4-1.6%, Chromium 11-13%, Silicon 0.15-0.35%, Magnesium 0.3-0.5%, Molybdenum 0.8-1.2%, Vanadium 0.2-0.5%

Thermic wood: Under the effect of heat (170-250°C) and steam the wood structure is changed and improved for special uses (e.g. in the kitchen) in a targeted and natural way without adding any chemicals. During the special treatment process, the cell wall structure is modified in such a way that the ability to absorb water is reduced and the resistance against bacteria is increased. The thermal treatment also lends the wood a slightly darker tone.

Stock Note: Not always held in stock. Please contact us for likely delivery timing. These knives are artisan made and not mass produced.

Care & Maintenence

|

Santoku - General Purpose Double bevel Blade 170 x 1.8mm 3 layers Overall 300mm Weight 130 gms

Item Code: F8090 |

|

Gyuto - Fish & Meat Double Bevel Blade 120 x 1.6mm 3 layers Overall 225mm Weight 50 gms

Item Code: F8091 |