Purchasing Options

French polishing is the name given to the highly evolved and beautiful wood finishing process based on the use of shellac resin. It reached its height of fashion and excellence in Victorian times across Europe. It is indelibly associated with the "Mahogany age" and remains a benchmark for wood finishing. Proponents will argue, with considerable authority, that there is simply no modern day finish which matches the all round beauty of a French Polished piece.

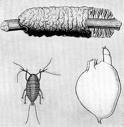

Shellac is a natural, organic resin derived from the secretions of lac insects which swarm in great numbers on certain host trees particularly in India the world's largest producer. Tree species favoured by the parasitic Laccifer lacca insect include Dalbergia odorifera, Albizia kalkora, Mallotus apelta, Campylotopis rockii and Ficus hookeriana. Lac insects incubate their young at their larval stage in the raw shellac casing by extracting colloid substances from the tree nutrients. The tree branches coated with the lac (known as Sticklac) are harvested and processed to offer the several grades and colours of shellac available. Lac is used in ink and pigments and was originally harvested for its wax content. Lac production is principally found in North-East India, Bangladesh, Myanmar, Thailand, Laos, Vietnam and parts of China.

|

|

|

Shellac is a versatile, wonder product which finds numerous other uses such as a glossing coating on confectionery, pharmaceuticals and fruit as it is food safe rated.

French Polishing

Although several natural and synthetic resins are used in wood coating products to enhance appearance and protect and preserve woodwork, none generate quite the reverence that shellac does. French polishing is the application of numerous coats of shellac, which has been made into a workable polishing resin by being dissolved in an industrial alcohol. It can be applied by brush or with a particular padding technique using a fad or tampon or rubber (all terms for the same hand applicator - a wad of cotton wool encased in a square of woven cotton cloth).

The process for large flat expanses such as table tops involves the repeated application of thin coats in circular and figure eight motions. A lubricating oil to prevent the fad from tearing into prior partly cured coats is needed when padding as are a range of pumice and tripoli (aka Rottenstone) powders for grain filling and abrading the surface.

The polish is also alternatively applied with fine brushes which leave little or no brush strokes.

A simple "French Polish" finish

Shellac is flexible enough to also offer a simple and fast curing day-to-day finish. An application of a couple of coats of polish - padded or brushed on - rubbed back between coats with very worn abrasive paper, with a final very thin coat and a topping wax is a legitimate and simple use of shellac which is part way to the full process. This is a repairable, durable, low toxicity finish well suited to cabinet pieces which will not have to withstand rough use such as coffee tables.

Shellac has several major positive attributes, high among them is that it is one of those few finishes which are re-constitutable which means new coats will meld with old and repairs and refurbishment is made very simple.

For a best selling title in print for Australian readers consider "A Polishers Handbook" by Neil Ellis. (at time of review May 2016 this excellent title is still out of print)

Storage & Shelf Life

Because shellac is an organic product it has a shelf life when purchased and stored dry. Old shellac past its use by typically fails to cure to the hard surface expected and remains tacky. When shellac is made up into an RFU (ready for use) polish its use by date is somewhat shortened particularly for de-waxed grades such as white and blonde and a useful rule of thumb is 18 months. Shellac still containing wax such as standard orange and button stores for around 24 months. This shelf life can be extended by storing both dry and RFU in a refrigerator .

Despite these cautions shellac is frequently successfully used over longer time frames especially for uses in woodturning where the heat generated when friction polishing seems to cure shellac for many years.

Making up a Polish

French polish is traditionally made up as a concentrate using a mix ratio of 1 part by weight shellac to 4 parts by liquid volume of alcohol e.g. 250 grams of shellac to 1 litre of spirits. This results in a 'four pound cut' and is as heavy a mix that will ever likely be used. Most polishers will then thin again 50:50 and work with a 2 pound cut. Where available 100% Denatured Absolute Alcohol Sprits (DAA) is very strongly recommended as the corner-hardware-store Methylated Spirits will contain some water which can cause problems getting the shellac into solution and may cause a white blooming in the finished work.

(Note: DAA is 100% ethyl alcohol (ethanol) with an added denaturant which distils at the same temperature as the ethyl alcohol and which renders the product undrinkable. This is for excise tax reasons. )

Popular Grades and Colours Available in Dry Form

|

|

|

|

|

|

|

| Orange | Waxy White | De-Waxed White |

Blonde | Garnet | Ruby | Button |