The Wood Works markets a wide range of tools and equipment for the beginner through to the professional carver.

We are agents in Australia for the Stubai range of carving tools and knives made in the valley of the Stubai in the Austrian Tyrol where these tools are, to this day, individually hand forged.

A hand forged tool is generally acknowledged as superior to CNC machined tools and Stubai offer a remarkable range of well over 1500 tool options.

In this data sheet

- Quick navigation to 11 Series of tools (if you know what you want)

- An explanation of the nomenclature (the coding system for the tools)

- Making your own set up

- Suggested starter sets

- A list of all available sets

- A more detailed navigation to each Series

- A ranking of world-wide sales volume for Series 52 and 55 (a very useful guide to what tools to start with)

- A brief history including manufacturing process

STUBAI CARVING CHISELS SERIES

Use these links to proceed directly to purchasing options

Untitled Document

|

Gold Flute |

100mm blade 200mm overall - 500+ options |

|

| Series 53 Fishtails |

56 options |  |

|

Rounded V |

6 options |  |

| Series 55 Polished Flute |

125mm blade 250mm overall - 260+ options |

|

| Series 58 Lino & Block |

51 options |  |

| Series 58 Micro - 100 mm Handles |

65mm blade, 165mm overall - 84 options |

|

|

H/Duty Fishtails |

28 options |  |

|

H/Duty Fishtails |

12 Options |  |

|

Violin Makers |

13 Options |  |

|

Stone Carvers |

13 options |  |

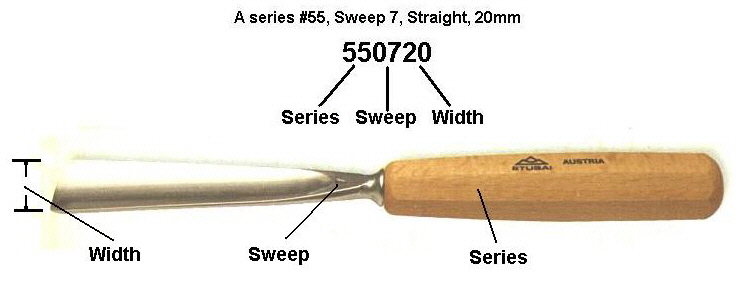

Tool Nomenclature (applicable for all other than Stone Carving)

Stubai chisels are described with a six digit code.

- The first two digits define the series (e.g 52, 55 etc.),

- The middle two digits define both the sweep and the style (the sweep meaning the cross sectional curvature of the flute and the style, defining the tool as a straight, a long bent, a short bent etc.)

- The fifth and sixth digits define the nominal width of the flute in millimetres (e.g anywhere from 2mm to 90mm - note that these tools are hand forged so minor variations are to be expected).

(Note that the style is defined within the sweep definition, for example a 5241 is straight, a 5242 is a long bent, a 5244 is a short bent, a 5234 is back bent and a 5268 is a fishtail etc).

Examples

The tool above, a 550720, is therefore a Series 55 with a 07 sweep, a straight style nominally 20mm wide.

A tool specified as a 524106 is therefore a Series 52 with a 41 sweep, a straight style which is nominally 6mm wide.

A tool specified as a 520110 is therefore a Series 52 with a 1 sweep, a straight style which is nominally 10mm wide.

A tool specified as a 520216 is therefore a Series 52 with a 1 sweep, a straight skewed style which is nominally 16mm wide.

A tool specified as a 522112 is therefore a Series 52 with a 1 sweep, a short bent right leading skew style which is nominally 12mm wide.

A tool specified as a 521216 is therefore a Series 52 with a 4 sweep, a long bent style which is nominally 16mm wide.

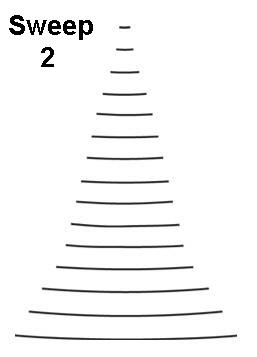

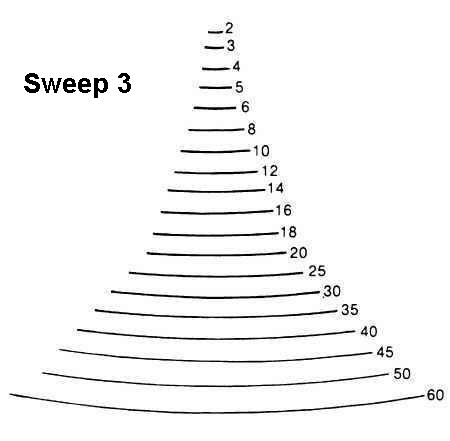

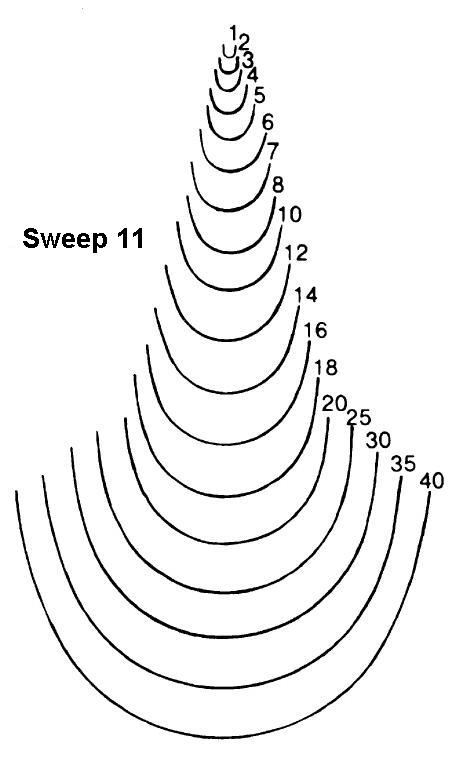

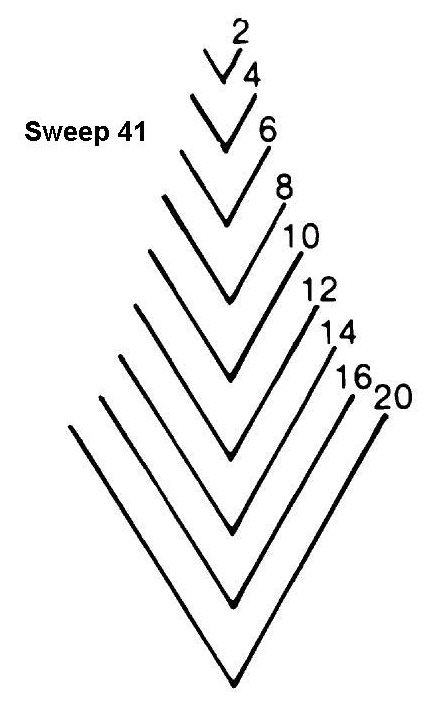

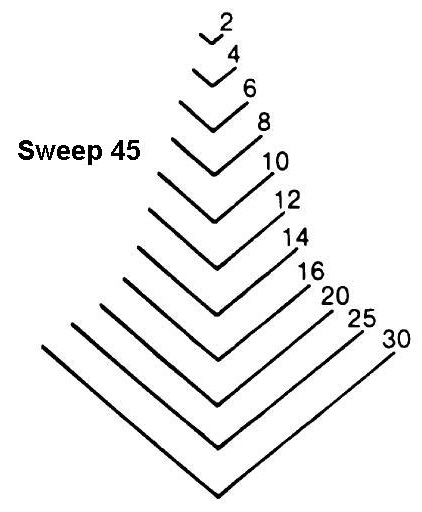

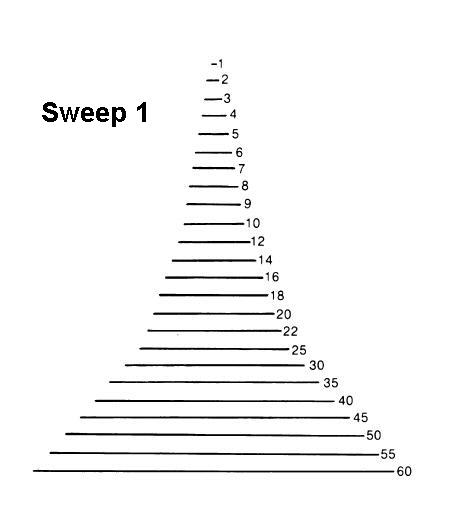

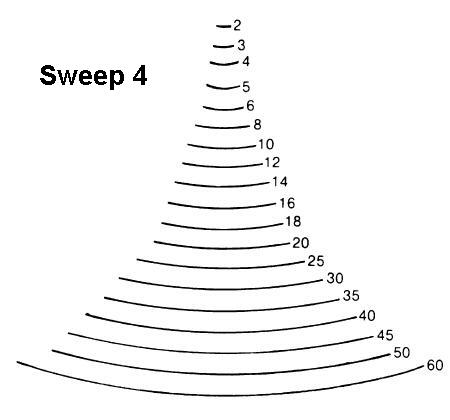

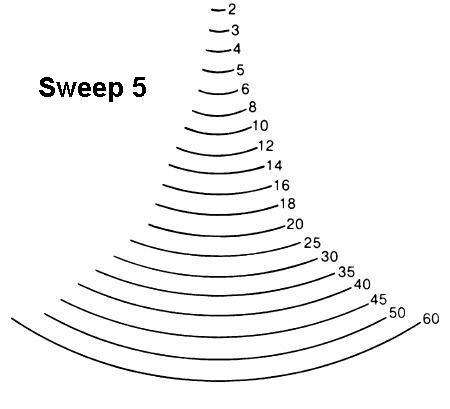

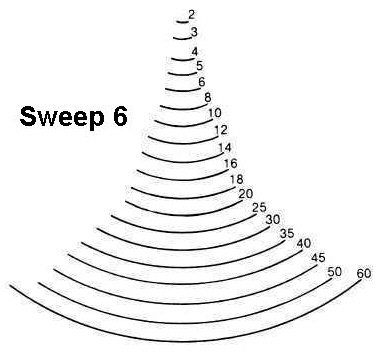

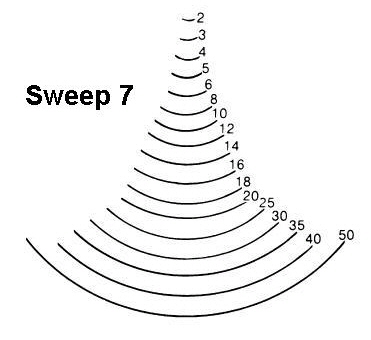

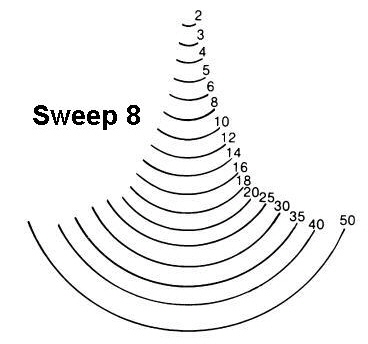

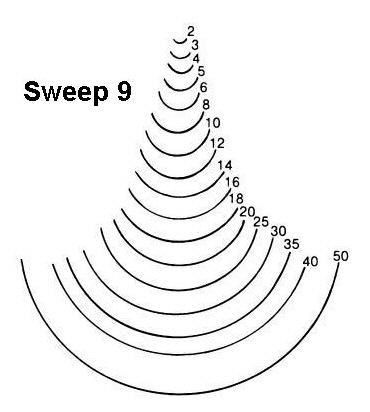

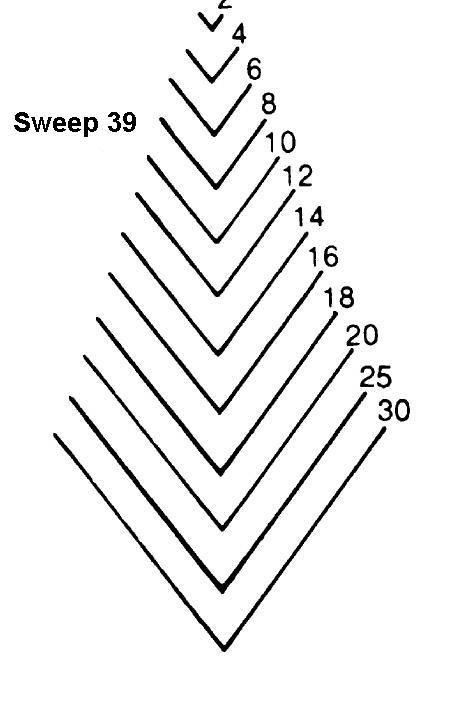

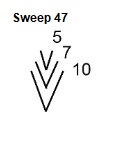

Sweeps

Some popular sweeps

(The German term stich, and English terms sweep and flute are all terms for the cross sectional shape of the blade.)

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Buying Sets & Making Up Your Own Set

The information on sets follows below. Note that you can if you wish make your own set up and we can package it and charge for it as a set. This suits buyers with a specialty carving interest. The only proviso is that the range of sizes and pricing approximates a standard set and that it may take us a while to assemble your set. Please email for further advice on this option.

Getting Started - links to two popular starter sets

An ideal way to get the first few tools together is to opt for one of the sets detailed below. Carving uses by far the most varied chisel patterns when compared with other woodworking pursuits however, a set of 6 in either Series 52 or Series 55, supplemented with a pattern 41 V tool, typically around 6mm, is the perfect introductory set.

- Series 52 set of 6 - CLICK HERE

- Companion tool to this set of 6 - 6mm Sweep 41 V tool in 52 series - CLICK HERE

- Series 55 set of 6 - CLICK HERE

- Companion tool to this set of 6 - 6mm Sweep 41 V tool in 55 series - CLICK HERE

Getting Serious - Full Listing Of Sets

Series 52

- Cardboard box set of 6 - CLICK HERE

- Cardboard box set of 7 (includes 2 knives) - CLICK HERE

- Set of 14 in a leatherette tool roll (includes a knife & slipstone) - CLICK HERE

- Set of 21 in a canvas roll (includes a mallet) - CLICK HERE

Series 55

- Cardboard Box set of 6 - CLICK HERE

- Wooden Box set of 6 - CLICK HERE

- Gift box set of 6 (includes DVD, paintset & brush and pre-roughed carving blank) - CLICK HERE

- Set of 20 in a canvas tool roll - CLICK HERE

Series 58

- Set of 6 - CLICK HERE

Violinmakers

-

Set of 6 - CLICK HERE

Tool Series - links to the most commonly purchased tool series

The principal series are 52, 55, 53 and 58.

Series 52 - in-line, octagonal handle with internal ferrule and heavy bolster. Treated flute to resist rust, ready honed, around 215mm overall. Total of 35 sweep/style options and approximately 500 tool options overall.

- Click HERE for Series 52 Catalogue .pdf download.

- Click HERE for Series 52 Tool sets

- Click HERE for Series 52 Straights

- Click HERE for Series 52 Long Bents

- Click HERE for Series 52 Short Bents

- Click HERE to see the Series 52 heavy duty sculptors fishtails

Series 55 - in-line octagonal handle with internal ferrule and heavy bolster. Polished flute, ready honed, around 250mm overall. Total of 32 sweep/style options and approximately 220 tool options overall.

- Click HERE for Series 55 Catalogue .pdf download.

- Click HERE for Series 55 Tool sets

- Click HERE for Series 55 Straights

- Click HERE for Series 55 Long Bents

- Click HERE for Series 55 Short Bents

- Click HERE to see the Series 55 heavy duty sculptors fishtails

Series 53 - fishtail style, in-line octagonal handle with internal ferrule and heavy bolster. Treated flute to resist rust, ready honed, around 215mm overall. There are 7 sweep options and 7 flute width options. The series 53 are similar to series 52 and are displayed in the series 52 catalogue.

- Click HERE for Series 53 catalogue page .pdf download.

- Click HERE for individual tool purchasing options.

Series 58 - either with classic lino palm handle or a set of 6 with 100mm down scale in line handle. Polished flute, ready honed, around 165mm overall. These tools are often known as block or lino cutters. There are 21 sweep and 50 flute width options.

- Click HERE for Series 58 catalogue page .pdf download.

- Click HERE for individual tool purchasing options.

- Click HERE for Series 58 Tool sets

Untitled Document

How To Choose

Of all the disciplines in wood working which use hand chisels, and it is difficult to think of any which do not, carvers use by far the widest range of patterns and sizes. There are many variants which can cause confusion for the beginner carver. Many of the more esoteric tool patterns are for unusual applications. The truth is about 6 tools will get you started and a serious set of tools will still likely number fewer than 30 tools.

The tables below are intended to assist with getting started and assist with selecting the most useful tools from those which are for specialised or obscure applications. The rankings indicate the top selling 100 tools across the Series 55 range followed by an outright ranking of sales of the Series 52. These rankings also inform our stocking decisions.

Note this represents Stubai sales worldwide across every carving discipline and national carving tradition so needs to be seen as a guide only. If for example you are interested in a specialty such as carving bowl or spoon shapes, these rankings are not so useful. If, on the other hand, your interests are mainstream, this is a most useful guide to what tools to purchase and in what order.

Series 55 Popularity Ranking

Ranking is by 5 groups of 20 tools and within each group they are ranked by purchase code NOT populartity, i.e a 41/12 is equal to a 01/20.

The F9999 structure codes are searchable Item Codes which we use in our website, the 01/20 structured codes are short hand, in this case, for a Sweep 1, 20mm etc.

| Rank | 1-20 | Rank | 21-40 | Rank | 41-60 | Rank | 61-80 | Rank | 81-100 |

| Code | Desc. | Code | Desc. | Code | Desc. | Code | Desc. | Code | Desc. |

| F5009 | 01/20 | F5002 | 01/04 | F5039 | 02/25 | F5332 | 06/06 | F5120 | 03/02 |

| F5122 | 03/06 | F5003 | 01/06 | F5124 | 03/10 | F5333 | 06/08 | F5123 | 03/08 |

| F5125 | 03/12 | F5006 | 01/12 | F5127 | 03/16 | F5334 | 06/10 | F5130 | 03/30 |

| F5128 | 03/20 | F5032 | 02/06 | F5157 | 04/20 | F5335 | 06/12 | F5132 | 03/40 |

| F5129 | 03/25 | F5035 | 02/12 | F5301 | 05/04 | F5336 | 06/16 | F5151 | 04/04 |

| F5302 | 05/06 | F5121 | 03/04 | F5303 | 05/08 | F5337 | 06/20 | F5152 | 04/06 |

| F5305 | 05/12 | F5156 | 04/16 | F5307 | 05/16 | F5423 | 07/08 | F5153 | 04/08 |

| F5308 | 05/20 | F5309 | 05/25 | F5424 | 07/10 | F5482 | 28/10 | F5158 | 04/25 |

| F5425 | 07/12 | F5421 | 07/04 | F5603 | 09/08 | F5544 | 08/08 | F5159 | 04/30 |

| F5427 | 07/20 | F5422 | 07/06 | F5604 | 09/10 | F5545 | 08/10 | F5306 | 05/14 |

| F5602 | 09/06 | F5426 | 07/16 | F5606 | 09/16 | F5546 | 08/12 | F5310 | 05/30 |

| F5605 | 09/12 | F5428 | 07/25 | F5667 | 11/10 | F5631 | 10/10 | F5338 | 06/25 |

| F5607 | 09/20 | F5601 | 09/04 | F5784 | 41/10 | F5662 | 11/03 | F5429 | 07/30 |

| F5661 | 11/02 | F5608 | 09/25 | F5900 | 47/05 | F5752 | 39/06 | F5431 | 07/40 |

| F5663 | 11/04 | F5665 | 11/06 | F5005 | 01/10 | F5753 | 39/08 | F5541 | 08/04 |

| F5668 | 11/12 | F5666 | 11/08 | F5008 | 01/16 | F5901 | 47/08 | F5547 | 08/16 |

| F5781 | 41/04 | F5780 | 41/02 | F5034 | 02/10 | F5001 | 01/02 | F5600 | 09/02 |

| F5782 | 41/06 | F5010 | 01/25 | F5154 | 04/10 | F5004 | 01/08 | F5632 | 10/16 |

| F5783 | 41/08 | F5031 | 02/04 | F5155 | 04/12 | F5033 | 02/08 | F5660 | 11/01 |

| F5785 | 41/12 | F5038 | 02/20 | F5304 | 05/10 | F5037 | 02/16 | F5664 | 11/05 |

Series 52 Popularity Ranking

The final table below indicates the top selling 40 Series 52 tools in outright popularity rank. The advice above about the usefulness of this advice should be noted.

| 1 | F4677 | 41/06 | #524106 |

| 2 | F4371 | 07/20 | #520720 |

| 3 | F4556 | 11/02 | #521102 |

| 4 | F4486 | 09/20 | #520920 |

| 5 | F4676 | 41/04 | #524104 |

| 6 | F4558 | 11/04 | #521104 |

| 7 | F4369 | 07/16 | #520716 |

| 8 | F4176 | 04/20 | #520420 |

| 9 | F4522 | 30/06 | #523006 |

| 10 | F4151 | 03/20 | #520320 |

| 11 | F4392 | 16/12 | #521612 |

| 12 | F4178 | 04/30 | #520430 |

| 13 | F4624 | 39/10 | #523910 |

| 14 | F4555 | 11/01 | #521101 |

| 15 | F4566 | 11/16 | #521116 |

| 16 | F4039 | 02/10 | #520210 |

| 17 | F4482 | 09/12 | #520912 |

| 18 | F4041 | 02/14 | #520214 |

| 19 | F4007 | 01/08 | #520108 |

| 20 | F4033 | 02/04 | #520204 |

| 21 | F4562 | 11/08 | #521108 |

| 22 | F4678 | 41/08 | #524108 |

| 23 | F4152 | 03/25 | #520325 |

| 24 | F4360 | 07/02 | #520702 |

| 25 | F4167 | 04/04 | #520404 |

| 26 | F4001 | 01/02 | #520102 |

| 27 | F4563 | 11/10 | #521110 |

| 28 | F4259 | 05/16 | #520516 |

| 29 | F4560 | 11/06 | #521106 |

| 30 | F4264 | 05/35 | #520535 |

| 31 | F4372 | 07/25 | #520725 |

| 32 | F4479 | 09/06 | #520906 |

| 33 | F4373 | 07/30 | #520730 |

| 34 | F4155 | 03/40 | #520340 |

| 35 | F4366 | 07/10 | #520710 |

| 36 | F4012 | 01/16 | #520116 |

| 37 | F4174 | 04/16 | #520416 |

| 38 | F4254 | 05/06 | #520506 |

| 39 | F4362 | 07/04 | #520704 |

| 40 | F4044 | 02/20 | #520220 |

Historical Notes and Tool Manufacture

The Stubai is an alpine region in the Austrian Tyrol where iron ore deposits have sustained a steel making and edge tool manufacturing industry for centuries. A vibrant carving tradition grew up around the steel making industry and locals, during long winters when work was scarce, would use the time to carve artwork and trade it for food and other essential items. The earliest of these pieces date back to the 14th century.

Stubai wood carving tools are a premium European brand with an extensive range of close to 1500 tool options in all. The hand forged tools have beech handles, a forged bolster and the majority of the range have a tang fitted into an internal steel ferrule which resists handle splitting.

Stubai maintain a tradition which for them is several hundred years old. They still make their carving tools by hand forging and grinding whereas other manufacturers have moved to CNC manufacture. Each tool is hammered out on a drop hammer powered by an in-house hyrdo-electric generator. The shaped tool then goes through many processes to finish as a hardened, honed and ready-for-use carving tool.

It should be borne in mind that these tools are individually hand forged by master toolmakers and not produced automatically by robotically driven machines. There will therefore be slight variations between identically specified tools.

The Series 55 tools have a polished flute, the Series 52 range have a golden coloured appearance applied during heat treating to minimise rust.

The tools are supplied ready honed with edges adequately buffed and not dubbed over. Stubai handles are machined from European White Beech and have either an octagonal cross section or machined flat which avoids the tool rolling about when put down on a bench. Many carvers gently sand the handle edges for a more comfortable feel. The 52 and 55 tools are made without external ferrules or hoops (at either end) or striker caps. The steel in these tools is equal to the best found in Western made carving tools.

Untitled Document

| Hammering the tang | Shaping the blade | |

|

|

Words from the makers:

Many factors are involved in the manufacture of a high quality carving tool and there are as many as 26 steps in the production process of completion of a tool.

The major steps are;

Forging: Raw material is forged into the basic form

Heating: With a longstanding experience the steel is beeing processed for forming

Forming: The approximate endform is accomplished during this process

Cooling: The tool is beeing cooled down for the first grinding process

Grinding: Carefully grinding is the key to a quality tool during this process. Since the tool has not been hardened yet.

Hardening and Heating: During this production step we accomplish the HRC 59-60

Polishing, sharpening and mounting the handle: Final steps can be applied to the tool.

We start with a top quality alloy steel for high edge-holding ability called “K 200” which depending on the availabilty is purchased in Austria (Böhler- Udeholm) or Germany (Thyssen) .

The K 200 Steel consists of: Carbon, Chrom, Mangan and Silizium

Production steps in order:

1) lengthening of the steel

2) handforging the shaft

3) lengthening to the tool length

4) handforging the basic form

5) heat treatment at 560° Celsius for 12 hours

6) trimming

7) pressing in the form

8) glowing: steel is being processed to be airtight, 710° Celsius for 36 hours

9) scrubbing in barrel to remove the forging scales

10) sorting

11) straightening

12) grinding the form lengthwise

13) grinding the sides to the exact width

14) sharpening

15) marking the sweep number

16) another process of straightening

17) hardening in salt bath

18) glowing, to reach the desired HRC

19) polishing the inside

20) polishing the outside

21) grinding the shaft

22) cleaning in gasoline bath

23) heating to 230° Celsius

24) polishing

25) sharpening the cutting edge

26) mounting the handle