Until relatively recent times tapered shank wood screws - usually with cut and not rolled threads - were the standard throughout much of the world. They have been made almost entirely redundant by parallel shank screws which often lack aesthetic appeal.

NOTICE: August 2021 we have just begun to offer a range of finished Phillips head steel screws in black, antique brass and antique copper -- See HERE

| Brass, Countersunk Slotted | Brass Countersunk Phillips |

|

Brass Raised Countersunk | Brass Raised Countersunk - Chrome Plated | Brass Round Head Slotted |

|

|

|

|

|

|

Head Patterns - Slotted countersunk, raised countersunk or oval and round head.

Driving standard - The adoption of a driving arrangement depends to a surprising degree on where in the world you work. A straight slotted drive is historically as old as screws but in modern times if you work in Canada or most parts of the USA square drives dominate, if you are in Europe PoziDrive (closely akin to Phillips) predominates, Phillips is common in many regions including Australia.

Countersink Angles - for the vast majority of screws an 82 degree countersink angle under the head of screws is standard. An exception may be for square drive heads where a 90 degree angle is popular to give room to put a square drive socket in the head.

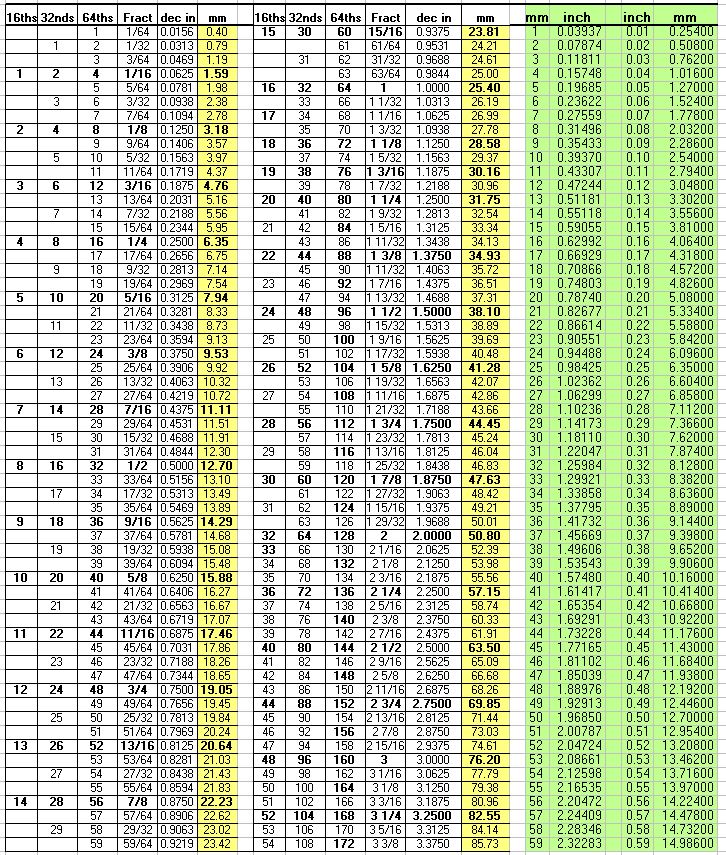

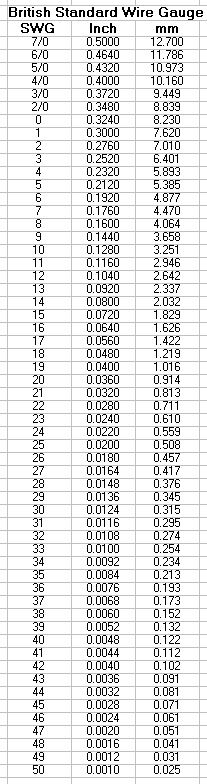

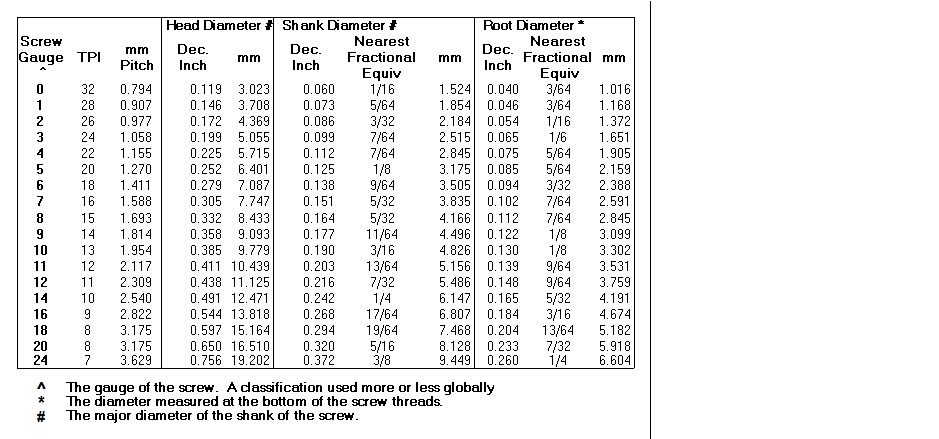

Gauges - Derived from British Standard wire gauge - BSWG or American Wire Gauge - AWG. The gauge system, which is still widely used in imperial measurement regions was created and survives fundamentally because the inch world has always been burdened with inches and fractions of inches and decimal inches are of very little use in describing dimensions for screws.

Cut versus rolled threads - Although technically a cut thread somewhat weakens the shank of a screw as opposed to a rolled thread where no base material is machined away a cut thread screw offers sharper threads which drive and hold more sweetly than a rolled thread. A cut thread screw is therefore deemed superior.

Base metals - For reasons of history and demand we offer screws predominantly made from brass complemented with a small selection of classic raw mild steel screws - the standard until the 1960's. Over the years many other metals have been used including raw mild steel, stainless steel, silicon bronze, high nickel alloy and others.

Coating Metals - Brass is frequently used to coat steel core screws offering Brass Plated Screws. We offer some solid brass screws with a faux antique coating.

Standards Organisations - Are national or international organisations which set standards for industry. ISO - International Standards Organisation, ANSI - American National Standards Institute, BS - British Standard, DIN - Deutsche Industry Norm, EN - European Norm are examples. The dimensions table below is indicative only as some regions of the world may not always comply with standard dimensions.

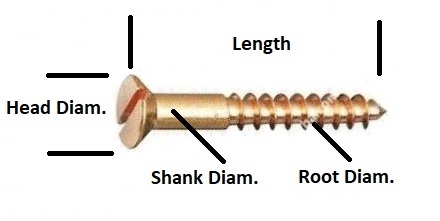

Major Dimensions

The root diameter is a reasonable guide to selecting a pilot drill - often indicated for inserting brass screws which are comparatively weak.

A Ready Reckoner Table