Of the several classes of Japanese woodworking tools which have been introduced to Western markets over the last few decades, it is hand saws which have been most widely accepted, followed probably in order by synthetic sharpening water stones (which also represent a remarkable advance on Western equivalents), chisels (which are in a class all of their own but require management of the ultra hard edge steel and rear scallops) and planes which are confronting to many because of their manual adjustment.

(An excellent read on the subject - Toshio Odate "Japanese Woodworking Tools: Tradition & Use")

Hand Saws

Travelling east from Europe the direction of teeth on hand saw blades change from pointing forwards to pointing rearwards. The cut is executed the same way, just the cutting stroke direction reverses. The reasoning is straightforward, saw blades cutting in expansion (the pull cut) can be finer and thinner than blades cutting in compression (the push cut).

A thinner saw will, by definition, and given the other elements relevant to the cut are more or less eqivalent, require less force applied for a given cut than a thicker saw. A comparison of a typical Western tenon saw and its Japanese Dozuki equivalent illustrates this difference clearly. The Western tenon saw has a kerf of about 1.2mm, the Japanese Dozuki typically 0.33mm. The tooth count for the Western tenon saw will likely be mid teens, say 15tpi (1.7mm pitch), and the Japanese 25tpi (1.0mm pitch). (See pitch tables HERE.)

Note: The deluxe options below are even finer with blade thickness of 0.2mm, kerf of 0.3mm and teeth pitch of 0.8mm (32 tpi).

To take this a bit further, a comparative assessment of these saws is interested in several factors including force required, cutting speed, smoothness & precision, cost and controllability.

Force applied is well understood, cut speed is a function of sharpness, applied force and the tooth count (fine tooth blades are inherently slower than coarser ones due to the tooth gullets loading up with waste), smoothness & precision are determined by technique, tooth count and the grinding precision of the teeth and cost is a given (currently a quality Sheffield brass back tenon is about 30% more than an equivalent Japanese dozuki) whereas controllability is definitely an issue which separates the two styles. Japanese saws typically have a finer blade cutting a very fine and precise kerf and they do not like to be redirected at the start of the cut as is possible with more crudely cut Western saws. The Japanese blades go where they are pointed and in this respect have a somewhat higher requirement for good technique on the part of the user. (Hint: While cutting monitor and keep consistent the shadow gap between the blade and the wood - in a dozuki with a 0.3 mm blade and a .033 kerf this gap is slight but it can be seen).

Despite this requirement for technique Japanese saws are a delight to get started and far superior to Western saws in this regard.

The magic then lies in the pull stroke, quality of the steel, the sophisticated tooth geometry (for crosscut blades in particular) and a supreme, centuries old metal smithing tradition such as exists in Japan. The result is the sensation that Japanese saws have become across discerning Western markets.

We at The Wood Works have marketed these saws for well over 20 years and for us they continue to outsell Western equivalents about 100 to 1. We offer a range of saws made by high precision machines in specialised factories and a deluxe range sourced from master blacksmiths producing what are in effect hand made saws. Most of the factory made saws are made by Gyokucho and have replaceable blades. The deluxe range have fixed blades for which we can quote for resharpening at source.

In this data sheet

- Tooth geometry explanation

- Saw construction

- A list of the classes of saw

- Terminology in use

- A table of the purchase options we offer

- More detail on each saw

- Recommended first purchases

Tooth Geometry

Crosscut Teeth

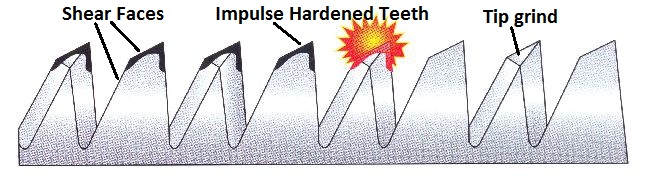

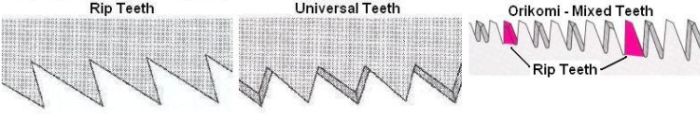

Crosscut teeth each have no fewer than three ground faces, all in shear, in contact with the wood during the cut. Rip teeth closely resemble western tooth patterns with a more or less vertical raker ground square across. To assist with getting rip cuts started the rip teeth of most ryobas are graduated in pitch, finer at the heel to larger at the tip. Universal teeth take some features from both crosscut and rip patterns and are preferred for dovetail cutting where angled end grain rip cuts have an element of crosscut.

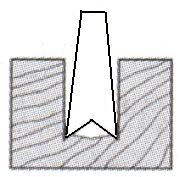

The majority of the saws we list are ground and set from ultra fine, flat steel plate, as thin as 0.2mm in the case of the deluxe range and, more typically for many dozukis, 0.3mm. Blades this thin require a stiffener. These thin blades mostly have set where the teeth are flared at their tip to provide clearance in deeper cuts. Exceptions are unset fret saws and unset flushcut saws neither of which are required to make deep cuts in which an unset blade might bind.

The orikomi blade uniquely has a few rip interspersed among crosscut teeth along the cutting edge.

Arborist saws have a thicker blade which is taper ground across their width. The specified thickness of these blades is measured from setless teeth of the cutting edge, the back of the blade is thinner to provide cut clearance. The side faces of these blades is typically ground smooth to prevent flared teeth scratching the cut faces of bonsai and similar.

Tapered Blade

Saw Construction

Many of the saws have a wooden handle wrapped with traditional rattan cane. This wrapping is very durable and if cared for will not unravel. Other saws have modern plastic handles. Some deluxe saws have resharpenable fixed blades which we can usually return to the makers for resharpening.

Most have replaceable blades with case hardened teeth which can be honed with special diamond feather files for those with the skill and the eyesight. These case hardened teeth last far longer than the resharpenable equivalent - we regularly replace blades after 8 or 10 years for customers who take good care of their blades.

Cheaper saws, especially those made outside Japan in Taiwan and China, have fully hardened teeth where the whole tooth is hardened. Gyokucho case harden their teeth one at a time which means the teeth have conventional, relatively flexible, tool steel in their core and a case of impulse hardened steel. The result is a greatly reduced incidence of teeth snapping off as is often the case with fully hardened teeth.

(For the technically minded "a cutting edge is heated for 0.003~0.005 seconds by applying an electrical current at 27.12MHZ. This creates a shock wave on the surface of each tooth that hardens it to Hv900~1200. For comparison, sharpening feather files are hardened to Hv800~850.").

Dozuki saws have a stiffener which is re-used when changing blades. An extended full length stiffener is available to suit Items T1400 and T1401.

To assist with rust prevention and reduce friction in the cut, Gyokucho blades have a microthin nickel coating which is applied chemically (not by electroplating). Despite this blades will rust (any quality steel will) so rust prevention practices are indicated.

See HERE for a selection of rust management products.

For saw care we market leather saw cases and edge guards.

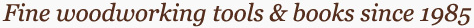

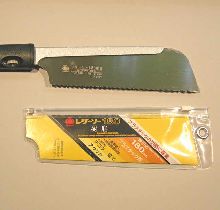

Our three best sellers from Gyokucho all have replaceable blades.

|

|

|

|

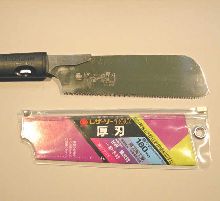

Gyokucho 'Sunchild' Dozuki blade and stiffener connection to can handle. Item T1400 |

Gyokucho 05 Kataba blade connection to cane handle. Item T1403 | Gyokucho 651 Ryoba blade connection to cane handle. Item T1405 |

Major Saw Classes with Site Links

- Dozuki - in both rip, crosscut & universal tooth - stiffened ultra thin blades equivalent to Western back saws

- Ryoba - double sided - crosscut teeth on one side and rip teeth along the other

- Kataba - backless & single sided for deep cuts

- Akagashi - make your own style saws from alternative handles and interchangeable blades

- Arborist & Bonsai Saws - tapered, setless blades

- Kobiki - crosscut and rip for large scale log, plank & beam work

- Keyhole - 'Mawashibiki' with Japanese tooth pattern

- Fret - with setless blade perfect for setting frets

- Flush Cut - called 'Kugihiki' in Japan, setless, shallow cutting thin blades

- Orikomi - fine and graduated tooth trades saws - folding

- Azebiki - double sided with curved shorter blades

- Fugaku - wood handles folding Dozuki and Kataba

Terminology

Class = the category of saw.

Overall Length = the overall length of the saw (unfolded where applicable).

Depth of cut = the maximum cut possible until the stiffener bears on the wood - pertains to dozukis.

Blade length = the length of the cutting edge - e.g 240 x 0.3 is a 240mm long 0.3mm thick blade.

Blade thickness = thickness of the blade steel. Note: some saws have setless, taper ground blades.

Set / Kerf = set is the flare on teeth needed for clearance, kerf is the width of cut made by the blade in the work.

Unset = a few blades have no set for shallow cuts where binding is not an issue.

Tapered = a blade which is ground to be thinner at the back edge than the cutting edge.

Pitch = the distance between teeth (Note: Ryobas have variable pitch rip side blades - finer at heel, coarser at tip).

TPI = Teeth per Inch - the most common method of denoting tooth spacing in the foot & inch world.

Crosscut = a blade optimised for cutting across grain.

Rip = a blade optimised for cutting down the grain.

Universal = a blade with teeth which cut either cross or rip.

Case Harden = certain Gyokucho blades have case hardened as opposed to cheaper fully hardened teeth.

Shear = an edge meeting the work it is cutting at an angle, not square on - aka skew.

Set/Kerf = the width of cut (kerf) determined by the flaring of the teeth (set).

White Paper Steel = special Japanese steel formulation used in the highest quality tools.

Blue Paper Steel = special Japanese steel formulation used in high quality tools.

High Speed Steel = HSS is a Western derived mass produced steel for edge tools - harder than tool steel.

Tool Steel = standard steel used for numerous edge cutting tooling - aka carbon steel.

Stainless Steel = so called steel formulated to not rust with edge holding ability greatly compromised.

Stiffener = some blades are so thin they require a stiffening spine which is reused when changing blades.

Folding = a few saws have blades which unlock and swing back into the handle for safe storage of blade.

Dual lock = folding saws with two alternative lock positions, in-line and about 20 degrees past in-line.

Cane = rattan cane traditionally used to wrap handles.

EVA = modern plastic handle material.

Turned up nose - some dozukis have a few setless leading teeth used to start cuts in panel stock - ply etc.

Item Code = the searchable code used to find the item in the website. Usually hyperlinked.

Table of Purchasing Options

For purchasing details use the code while searching at www.thewoodworks.com.au

Saw by Saw Detail

| Dozukis |

|||||

|

|

|

|

|||

|

'Sunchild' Dozuki Saw 240 x 0.3 mm blade 1.3 mm pitch, universal tooth Stiffened - Cane Handle BEST SELLER BUY NOW Item Code: T1400 |

ZA Dozuki Razor Saw 240 x 0.3 mm blade 1.5 mm pitch, crosscut tooth Stiffened - Cane Handle BEST SELLER BUY NOW Item Code: T1401 |

Dozuki Noko Saw 180 x 0.3 mm blade 1.0 mm pitch, universal tooth Stiffened - EVA Handle VERY FINE CUT BUY NOW Item Code: T1389 |

|||

| . | |||||

| . | |||||

|

|

|

|

|||

|

Usuba Dozuki Saw 180 x 0.3 mm blade 1.5 mm pitch, universal tooth Stiffened - EVA Handle Turned Up Nose BUY NOW Item Code: T1385 |

Jushi Dozuki Saw 180 x 0.3 mm blade 1.5 mm pitch, universal tooth Stiffened - EVA Handle

BUY NOW Item Code: T1387 |

Deluze Dozuki Crosscut 180 x 45 x 0.2 mm blade 0.8 mm pitch, crosscut tooth Stiffened - Cane Handle 32 tpi, Kerf 0.3mm BUY NOW Item Code: T1320 |

|||

| . | |||||

| . | |||||

|

|

|

|

|||

|

Deluze Dozuki Crosscut 240 x 50 x 0.2 mm blade 0.8 mm pitch, crosscut tooth Stiffened - Cane Handle 32 tpi, Kerf 0.3mm

BUY NOW Item Code: T1321 |

Deluze Dozuki Ripsaw 240 x 45 x 0.25 mm blade 0.8 mm pitch, rip tooth Stiffened - Cane Handle 32 tpi, Kerf 0.35mm

BUY NOW Item Code: T1324 |

Dozuki Folding Crosscut 240 x 45 x 0.60 mm blade 0.9 mm pitch Stiffened - EVA Handle Tapered & Setless

BUY NOW Item Code: T1399 |

|||

|

|

|

|||

|

Dozuki Noko Rip

240 x 50 x 0.3mm blade - Item: T1395 1.0 mm pitch, rip tooth Fully Stiffened - Cane Handle 25 tpi, Kerf 0.33mm |

Fugaku Dozuki SUPER HARD

240 x 40 x 0.3mm blade - Item: T1381 1.5 mm pitch, crosscut tooth Stiffened - Folding Wood Handle 17 tpi, Kerf 0.33mm |

||||

| . | |||||

| . | |||||

|

|||||

|

Fugaku Dozuki UNIVERSAL

240 x 40 x 0.3mm blade - Item: T1382 1.5 mm pitch, crosscut tooth Stiffened - Folding Wood Handle 17 tpi, Kerf 0.33mm |

|||||

| . | |||||

| . | |||||

| Ryobas | |||||

|

|

|

|

|||

|

Ryoba 240 x 0.45 mm blade 1.2mm crosscut-2.5~3.5 mm rip Double Sided - Cane Handle BEST SELLER BUY NOW Item Code: T1405 |

Ryoba 180 x 0.5 mm blade 1.5mm crosscut-2.7~3.5 mm rip Double Sided - EVA Handle

BUY NOW Item Code: T1404 |

Deluxe Ryoba 240 x 105 x 0.3 mm blade 1.4mm crosscut-3.0~4.5 mm rip Double Sided - Cane Handle White Paper Steel BUY NOW Item Code: T1352 |

|||

| . | |||||

| . | |||||

| Katabas | |||||

|

|

|

|

|||

|

05 Kataba Razor Saw 255 x 0.5 mm blade 1.3 mm pitch, crosscut, Stiffened - Cane Handle BEST SELLER BUY NOW Item Code: T1403 |

Atsuba Dozuki Saw 180 x 0.5 mm blade 1.5 mm pitch, universal tooth Non Stiffened - EVA Handle Turned Up Nose BUY NOW Item Code: T1386 |

Folding Kataba Saw 240 x 45 x 0.7 mm blade 1.1 mm pitch, crosscut tooth Tapered - EVA Handle Dual lock position BUY NOW Item Code: T1402 |

|||

|

|

|

||||

|

HSS Kataba Saw 265 x 60 x 0.6 mm blade 1.1 mm pitch, crosscut tooth Tapered - Cane Handle Dual lock position BUY NOW Item Code: T1326 |

Kataba Saw 250 x 60 x 0.6 mm blade 1.1 mm pitch, rip tooth Cane Handle Pitch 2.2~3.4mm BUY NOW Item Code: T1327 |

Kataba Mini Deluxe 60 x 20 x 0.3 mm blade 1.0 mm pitch, crosscut tooth Wood Handle 300mm Overall BUY NOW Item Code: T1336 |

|||

|

|

|

|||

|

Kataba Mini Deluxe 120 x 30 x 0.3 mm blade 1.0 mm pitch, crosscut tooth Wood Handle 330mm Overall BUY NOW Item Code: T1337 |

Akagashi Kataba 270 x 60 x 0.6 mm blade 1.9 mm pitch, crosscut tooth Universal Blade Interchangeable blade BUY NOW Item Code: T1287 |

Akagashi Kataba 270 x 60 x 0.6 mm blade 1.9 mm pitch, crosscut tooth Rough Cut Blade Interchangeable blade BUY NOW Item Code: T1288 |

|||

|

|

|

|

|||

|

Akagashi Kataba 250 x 60 x 0.5 mm blade 1.4 mm pitch, crosscut tooth Fine Cut Blade Interchangeable blade BUY NOW Item Code: T1289 |

Akagashi Kataba 150 x 23 x 0.3mm blade 1.0 mm pitch, crosscut tooth Extra Fine Cut Blade Interchangeable blade BUY NOW Item Code: T1290 |

Akagashi Kataba 210 x 35 x 0.6 mm blade 1.9 mm pitch, crosscut tooth Rough Cut Blade Interchangeable blade BUY NOW Item Code: T1291 |

|||

|

|||||

|

Fugaku Folding Kataba 240 x 35 x 0.6 mm blade 1.9 mm pitch, crosscut tooth BUY NOW Item Code: T1383 |

|||||

| . | |||||

| . | |||||

| Kobiki & Azebiki | |||||

|

|

|

|

|||

|

Kobiki Deluxe Crosscut 450 x 85 x 1.0 mm blade Pitch 3.3 mm, crosscut tooth Wood Handle LARGE SCALE WORK BUY NOW Item Code: T1340 |

Kobiki Deluxe Rip 450 x 85 x 0.8 mm blade Pitch 6.3~7.5mm, rip tooth Wood Handle LARGE SCALE WORK BUY NOW Item Code: T1343 |

Azebiki Deluxe 90 x 70 x 0.45 mm blade Pitch 1.2 crosscut, 3.3mm rip Cane Handle DOVETAILS & PANEL CUTS BUY NOW Item Code: T1439 |

|||

| . | |||||

| . | |||||

| Flushcut | |||||

|

|

|

|

|||

|

Flushcut Mini 125 x 30 x 0.3 mm blade 1.0 & 1.3mm pitch, Crosscut tooth DOUBLE SIDE BUY NOW Item Code: T1373 |

Flushcut 'Kugihiki' 190 x 40 x 0.3 mm blade 1.0 mm pitch, crosscut tooth Cane Handle DELUXE MODEL BUY NOW Item Code: T1370 |

Flushcut Akagashi 240 x 0.3 mm blade 1.3 mm pitch, universal tooth Stiffened - Cane Handle Interchangeable blade BUY NOW Item Code: T1292 |

|||

| . | |||||

| . | |||||

| Keyhole or Compass | |||||

|

|

|

|

|||

|

Keyhole Saw 210 x 5~14 x 1.3mm blade 1.6 mm pitch, crosscut tooth Kerf 1.4mm Wood Handle BUY NOW Item Code: T1360 |

Keyhole Saw 120 x 3~14 x 0.6mm blade 1.3 mm pitch, universal tooth Kerf 0.7mm Wood Handle BUY NOW Item Code: T1361 |

Keyhole Saw 150 x 10~15 x 0.6 mm blade 1.6 mm pitch, crosscut tooth Kerf 0.8mm Interchangeable blade BUY NOW Item Code: T1293 |

|||

| . | |||||

| . | |||||

| Orikomi & Arborist | |||||

|

|

|

|||

|

Orikomi Saw 250 x 0.8mm blade Mixed Crosscut & Rip teeth Pitch 2.5mm Folding Plastic Handle BUY NOW Item Code: T1436 |

Pocket Boy Coarse 130 x 30 x 0.9mm blade T1000 170 x 30 x 1.0mm blade T1001 Folding Plastic Handle Tapered blade

|

Pocket Boy Fine 170 x 30 x 0.85mm blade 1.6 mm pitch, crosscut tooth Folding Plastic Handle Tapered blade BUY NOW Item Code: T1021 |

|||

| . | |||||

| . | |||||

| Fret, Veneer & Restauro | |||||

|

|||||

|

Deluxe Fret Cutting Saw Blade 120 x 20 x 0.57mm Tooth pitch 1.1mm Kerf 0.57mm NO SET BUY NOW Item Code: T1363 |

'Restauro' Kataba Saw Blade 100 x 20 wide x 0.3mm Tooth pitch 1.0mm NO SET Kerf 0.3mm BUY NOW Item Code: T1338 |

Recommended First Purchases

The market speaks with authority on the order of purchase so consider these saws first unless you have a speciality interest such as cutting fret slots in guitar necks.

T1400 - Sunchild Dozuki. This is our (and the world's) best selling Japanese saw formula - 240 x 0.3mm fine cut.

T1405 - 651 Ryoba. Superbly useful saw with a rip side and a cross cut side.

T1403 - 05 Kataba. When you need depth of cut.

Untitled Document

Untitled Document